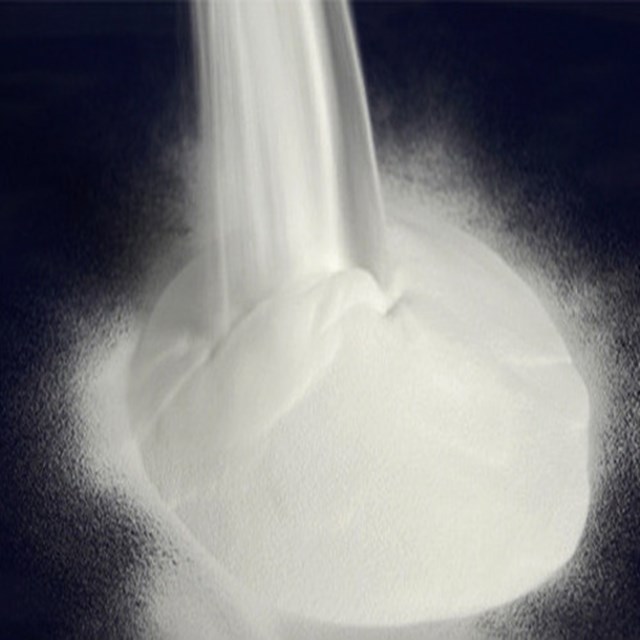

PVC Resins: The Backbone of Modern Manufacturing

Polyvinyl chloride (PVC) resins are one of the most versatile and widely used materials in the world. Known for their durability, adaptability, and cost-effectiveness, They play a crucial role in various industries, from construction to healthcare.

What Are They?

They are a type of synthetic plastic polymer made from the polymerization of vinyl chloride. lightweight, strong, and resistant to environmental degradation, making them ideal for a range of applications. They can be rigid or flexible, depending on the additives used during processing.

Applications

PVC resins have a broad spectrum of uses, thanks to their customizable properties:

- Construction: PVC is commonly used in pipes, window frames, flooring, and roofing materials due to its strength and weather resistance.

- Healthcare: Medical tubing, blood bags, and IV containers often rely on flexible PVC for its biocompatibility and safety.

- Electrical: PVC is a go-to material for insulating wires and cables because of its excellent electrical properties.

- Consumer Goods: From credit cards to packaging materials, PVC resins are present in many everyday items.

Benefits of PVC Resins

- Durability: They provide a long lifespan, even under extreme conditions.

- Versatility: Their ability to be molded into rigid or flexible forms makes them suitable for countless applications.

- Cost-Effectiveness: It is affordable to produce and maintain.

- Eco-Friendliness: Modern recycling technologies allow for the reuse of PVC products, reducing environmental impact.

It continue to revolutionize manufacturing, offering a balance of performance, affordability, and sustainability. Their adaptability ensures they remain a key material in innovation and production. Contact us